Crushing and screening solutions for iron and steel slag

For the extraction of secondary raw materials from slag or for the pure crushing of long reinforced concrete parts.

For the extraction of raw materials from slag or for the unmixed crushing of railroad sleepers or reinforced concrete, with crushers, screening plants and vibro-chutes from Neuson Hydrotec you define the powerful and efficient system solution tailored to your applications. Mobile or stationary.

HARD. HARDER. NEUSON.

Heavy duty screens & crushers

Hard. Harder. Neuson.

Heavy duty screens & crushers

Steel industry & Scrap Cleaning

Slag from steel production is bound value. How can the iron content of the slag, which is often only stored temporarily, be activated?

How do you clean and separate scrap into magnetic and non-magnetic parts? (Scrap Cleaning)

Recycling industry

Old must become the raw material for new. How do you recycle railroad sleepers? How do you recycle reinforced concrete beams and columns (e.g. demolition, earthquakes, etc.)?

With our robust systems, we are the partner of choice for the steel industry and waste disposal companies.

Let us know your general conditions at

and let us clarify your requirements.

Your

advantages

From individual components to customized complete solutions. Which crushing, screening and separating unit and which vibro-conveying technology is most efficient for your application?

System competence

Slag and hard rock processing, we look at the overall system and work with you to design an efficient and powerful solution.A specified system is more productive than the sum of its individual components.

Economic efficiency

Optimum dimensioning and short distances are essential. Dimensioning processing plants individually for your production process is crucial for the economic recovery of iron from the slag.

Sustainability

Efficient systems for a minimal carbon footprint. The comprehensive processing of the slag in the overall system minimizes the consumption of resources and protects the environment, making a significant contribution to sustainability.

System competence

Slag and hard rock processing, we look at the overall system and work with you to design an efficient and powerful solution.A specified system is more productive than the sum of its individual components.

Economic efficiency

Optimum dimensioning and short distances are essential. Dimensioning processing plants individually for your production process is crucial for the economic recovery of iron from the slag.

Sustainability

Efficient systems for a minimal carbon footprint. The comprehensive processing of the slag in the overall system minimizes the consumption of resources and protects the environment, making a significant contribution to sustainability.

Steel slag contains valuable iron!

Conventional crushers are not designed for this.

Extracting this valuable resource from the slag and feeding it back into steel production increases economic efficiency and reduces the carbon footprint of your production.

Robust machines.

Modular systems.

Robust machines.

Modular systems.

Breaking technology

As a hydraulics and mechatronics expert with expertise in heavy mechanical engineering, Neuson Hydrotec produces top-class crushing plants.

The mobile ST01BB crusher with crawler chassis or the stationary SOLO. The crushers are dimensioned specifically for productivity and efficiency and designed precisely for the consistency of your slag or crushed material. Longevity and low maintenance are must-have criteria for us.

Advantages of Neuson Hydrotec crushing plants

Hydraulic overload protection

Without interruption

Patented system

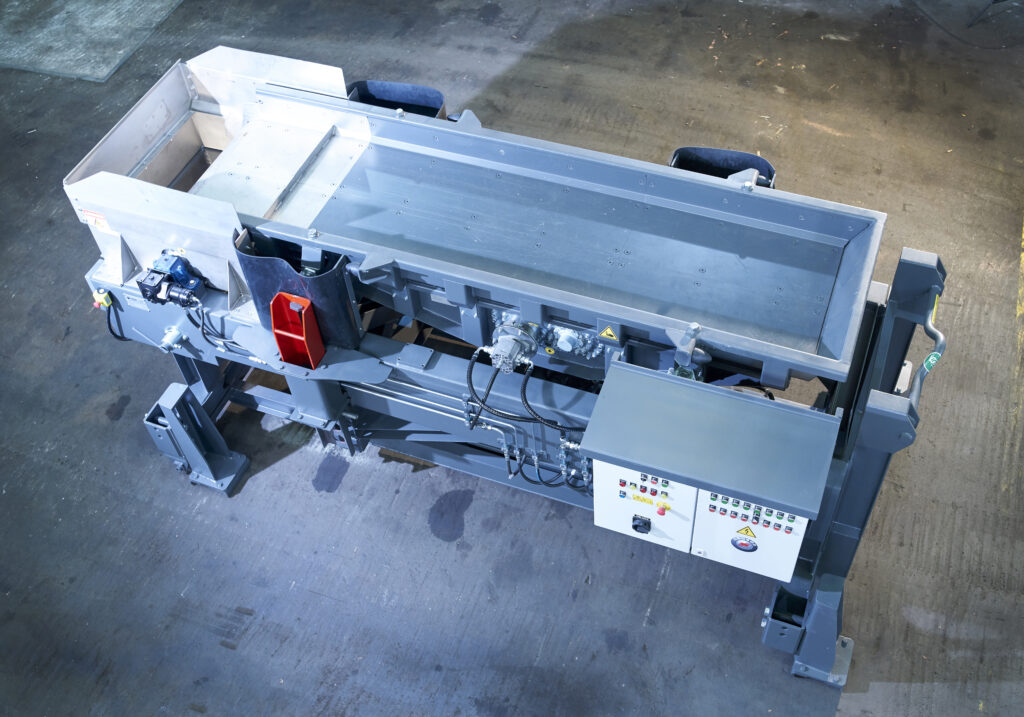

Sieve & separation unit

Screening and separation systems from Neuson Hydrotec are designed for slag and hard rock.

Advantages of the Neuson Hydrotec screening & separating unit

The powerful sieve

Efficient processes

Minimization of downtimes

Conveyor technology

Advantages of vibro-channels

Wear-free

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Advantage 2

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Advantage 3

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

High intensity separator

Light magnetic alloys such as ferrochrome in the slag are difficult to separate using conventional magnetic separators. However, the higher the degree of purity of the slag, the more valuable it becomes as a secondary raw material.

Neuson Hydrotec has developed the high-intensity separator HIAB1000 in order to be able to use slag with a high degree of purity as an additive in the cement and fertilizer industry.

With the HIAB1000, we are setting new standards in slag processing and contributing to the sustainable use of resources.

Advantages of the Neuson Hydrotec high-intensity separator

Individual magnetic drum

The heart of the system, a 5000 gauss magnetic drum, reliably separates weak magnetic components from the ironworks slag.

Different magnetic field depths are available depending on the size of the grain to be processed.

Reliable execution

Our tailor-made solutions are characterized by their robust design and specific adaptation to your requirements, resulting in minimal downtimes. Thanks to their simple design, our products are particularly easy to maintain and service.

Powerful

Depending on the design and grain size, our machines can process up to 50 tons of material per hour. The hydraulic drive ensures high durability, a long service life and excellent resistance to unfavorable weather factors.

With the robust jaw crushing and screening plants from Neuson Hydrotec, you set standards in the processing of slag.

Customized systems

With robust crushers, correctly dimensioned screening technology and material logistics tailored to the specific application (feeding, removal of fractions, transport chutes, conveyor technology), we offer efficient and customized solutions for particularly hard materials. The most efficient systems are created when the components are matched to the specific application and the specific material properties.

Advantages of customized systems

Optimized processes

The Neuson Hydrotec system solution ensures that everything is correctly dimensioned and perfectly coordinated, from the material feed to the crushing and screening plant to the discharge. This gives you an efficient and sustainable solution.

Economically strong

Your market, your knowledge

What questions do you have?

Write us what you want to know. Or would you like to talk to our experts? Together we will clarify your specific requirements.

Process &

Collaboration.

Those who work with Neuson Hydrotec benefit from a clear process from the initial inquiry to the provision of the solution:

Case Studies

German steel mill relies on proven quality!

Two years ago, the outdated stationary crushing plant for processing the LD and HO slag was replaced by the Neuson Hydrotec assembly teams.

And now?

Please ask us for details or technical data and test reports.

FAQs

The single-toggle jaw crusher is the most cost-effective crushing option due to its design. The crushing plates have a mineral-dependent service life of up to 3000 working hours.

The ST01BB is designed for crushing slag and hard rock.

Its unique design with the patented release system makes it the ideal universal crusher for iron and steel slag.

Slag from ironworks contains residual iron that adheres to the slag during skimming. Different production processes leave between 5 and 50% “residual iron” in the slag.

This raw material can be fed back into the smelting process. The iron-free residual slag is an important secondary raw material in road construction, for example.

Slag is a very abrasive material that often contains so-called iron bears (large unbreakable pieces of iron). If an iron bear gets into an impact mill, this leads to severe damage to the crushing chamber and the blow bars.

In conventional jaw crushers without a release system, an iron bear causes the crushing plates to break or production to stop, as the iron bear has to be removed manually.

With the ST01BB, the crushing chamber opens hydraulically, allows the iron bear to fall through and closes again to the set gap dimension.

Due to their design, jaw crushers are particularly suitable as primary crushers. Due to the type of crushing process, comparatively little fine grain is produced. The use of a screen is recommended to produce a defined final grain.

The MRP was designed to produce several (up to 3 classifications) end products in a single operation. With up to 3 individually configurable magnetic separators, it can freely produce 3 slag end products FE.

Conventional screening machines can make several separating cuts, but can only separate the classifications into metallic and slag parts in downstream work steps. Each additional work step costs money and time. The MRP40300 completes the task in a single work step with a capacity of up to 300 tons/hour.

Yes, because it is more cost-efficient to bring the machine to the material than to bring the material to the machine.

The open design of the MRP means that screen linings can be replaced quickly. It is not necessary to dismantle the upper deck to replace the screen linings in the lower deck.

Yes, the MRP can be configured with a diesel engine, with an electric motor, with both units in full drive and, if equipped with an electric motor, with an auxiliary diesel for moving the machine.

Thanks to its horizontal design, the MRP can convey stones, slag or iron bears weighing several tons. Hydraulic stones with a size of up to 350 mm can be classified as end products.

Processing technology

Processing technology

Your contact for processing technology

Horst Burger

Head of processing technology

“With Neuson Hydrotec heavy-duty crushing and screening plants, you can achieve top performance in the recycling of steel slag, hard rock and ores as well as in sorting and magnetic separation. They overcome material limitations and maximize the recovery of valuable resources into profitable raw materials. Neuson Hydrotec crushing and screening technology for your competitive edge!”

Your customer service contact

Jürgen Grammer

Customer service & aftersales

“Purchasing products from Neuson Hydrotec is not the end of a sales process, but the beginning of a responsible relationship with our customers. With the Service Center, we offer comprehensive maintenance and repair services as well as a huge selection of spare parts for Neuson components and certified commercial products to anyone who appreciates good service.”